Protect Your Profit Margins.

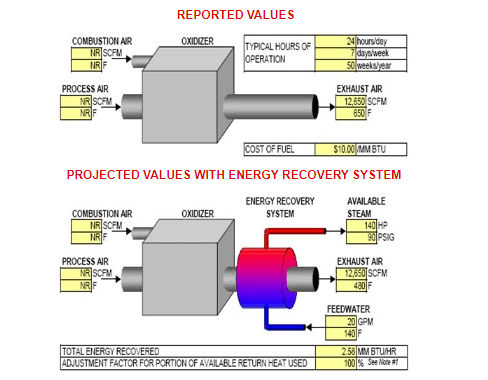

Anguil’s Engineering expertise and flexible solutions ensure payback and optimized performance so your plant can reduce operating costs and greenhouse gas emissions.

Applications

Applications

- Process Water or Air, Heating or Cooling

- Plant Comfort Heat

- Parts Drying

- Air Pollution Control

- Preheated Combustion Air

- Heated Process Water

Challenges

Rising fuel and electricity costs, coupled with global warming concerns have changed the way industrial facilities view energy consumption. Process equipment and pollution control systems that were installed several years ago may not reflect the energy conscious designs available today. Analyzing these systems to determine energy reduction opportunities can be a very valuable practice. Recovering waste heat is one of the easiest and most utilized means of reducing energy demands at industrial facilities.

Are you facing any of these challenges?

- Rising plant operating costs

- Inefficient, aging equipment

- Community or corporate pressure to reduce your environmental footprint