The Anguil Advantage

Upwards of 80% of the heat energy in VAM can be converted to usable energy, while experts predict that more than 50% of all VAM is exhausted from mine ventilation systems and remains unutilized. Anguil has developed a unique Regenerative Thermal Oxidizer (RTO) solution for VAM emissions, referred to as a VAMTOX, designed to harness the power of VAM as a reusable energy source that can even be sold for profit.

Instead of venting the methane to the atmosphere, Anguil’s VAMTOX technology can be combined with an energy recovery system for steam, heat, or electricity production. That energy can be recovered and converted into heated process air, plant heat or even electricity. These projects can often be funded without using extensive capital resources when the carbon credit and electrical power potential is considered.

The sheer volume of air coming from the mine shafts is massive and can vary greatly. Anguil’s VAMTOX oxidizer is designed to handle the large volume / low concentration stream yet is also capable of adapting to emission and flow spikes. Our proprietary hot gas bypass dampers are designed to handle these conditions without going offline or overheating.

Employee safety, environmental compliance, and system efficiency is at the forefront of Anguil’s solutions for VAM emissions. Anguil supplies turnkey abatement solutions, which can include civil, soil, mechanical, and electrical permits as well as installation. Our systems are designed to comply with state, federal and company safety standards.

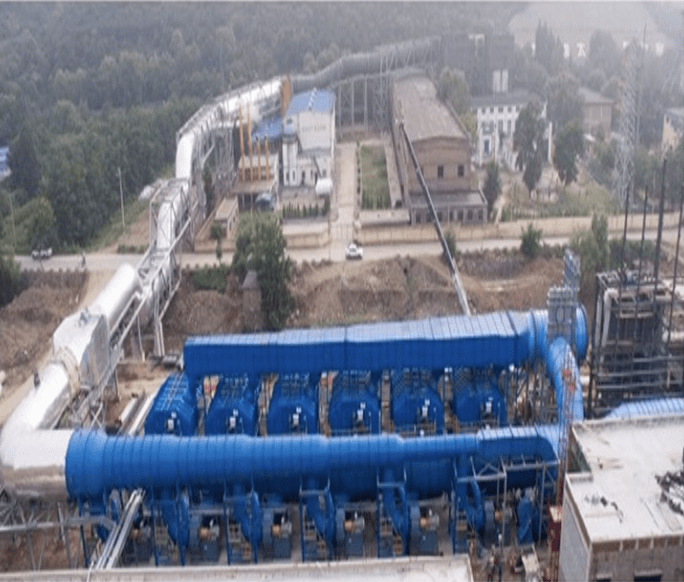

Anguil VAMTOX systems are suitable for installation in remote locations of mining operations, natural gas operations and petroleum refineries. The oxidizer and capture enclosure can be modular in design to allow for mobility, should the system be moved to another location once a mine has been closed.

We monitor and maintain methane values so that the thermal oxidizer is self- sustaining and requires little supplemental fuel. Computational fluid dynamic modeling and real time monitoring within the Anguil system ensure destruction efficiencies are met and the equipment will last.

For companies in the mining industry with wastewater treatment requirements, Anguil can be your single source provider of an integrated treatment train. Whether you are dealing with cyanide from an abandoned gold mine or total suspended solids (TSS) from an active site, we take a holistic approach to your application and explore all options for water reuse and onsite treatment. Anguil’s proven project development approach leverages attentive client collaboration, flexible exploration of viable treatments, rigorous solutions testing, and masterful integration with advanced controls and automation capabilities.

System Solutions

We custom engineer each solution, but Anguil finds the following technologies to be especially effective for VAM industry applications:

- Regenerative Thermal Oxidizer (RTO)

Often referred to a VAMTOX in this industry, the Regenerative Thermal Oxidizer (RTO) is the best abatement device for VAM, but it is certainly not a standard RTO application. These systems must be built conservatively and with great flexibility to ensure continuous operation. Most mine operators demand that the emission control system and related hooding for collection have zero impact on the operation and employee safety.