This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The Challenge

The Challenge

A food products company that mixes various types of waxes and other components to make the base for chewing gums was faced with the issue of cleaning up a slightly odorous, visible emission being exhausted from two of their process lines. The components of the emission were hot particles of chewing gum and some volatile organic compounds (VOC’s). The particles would quickly clog a conventional filter system or electrostatic precipitator, neither of which could control the odor off the process line. In addition to the emission problem, the condensation of the exhaust stream was damaging the roof of the facility.

The Solution

After thorough technical evaluation, the Self-Cleaning Ceramic Filter (SCCF) was recommended as the ideal solution for processing the exhaust and Anguil Environmental Systems was selected to solve the visual, odor and VOC problem.

The Result

In order to demonstrate to the client that this was a viable solution, Anguil utilized their portable self-cleaning ceramic filter test unit before any purchase decisions were made. During the test, the process lines were run through the ceramic filter in two modes, hot and cold.

First, the system was run in the hot mode with a gas burner firing continuously at 400º-500ºF heating up the process air. The once visible plume disappeared as it passed through the ceramic filter and catalyst module. Second, the ceramic filter was used without heat, and again, the visible plume disappeared as it passed through the ceramic filter and catalyst module. Twenty-four hours of production were run across the ceramic filter without heat and the visible emission was acceptable from a customer and environmental regulation standpoint. However, when utilizing a cold process stream, particulate matter accumulated on the ceramic filter which had to be periodically cleaned by firing the burner. When the cleaning cycle began after the two shifts, a dense white plume was emitted for 90 seconds while the filter element was burned clean. The customer, a food products company, felt that this emission level was not acceptable so they decided the continuous hot running ceramic filter would better fit their needs. It should be noted that for certain operations with visible emissions, the pulse cleaning mode may be acceptable. Many local authorities allow companies to discharge up to five minutes per hour without control.

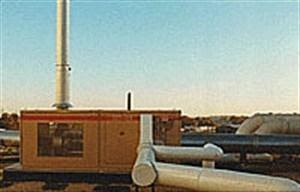

After the customer determined that the ceramic filter would solve their problems, Anguil proceeded to manufacture and install a 1,000 SCFM (1,577 Nm3/Hr) ceramic filter unit. The unit was used to process the exhaust from two process lines. One of the more significant benefits to the company was Anguil’s ability to reduce the air volume from the processes. Initially, the two gum-based mixers each had a 3,000 SCFM (4,731 Nm3/Hr) high volume, low static pressure fan that was exhausting to atmosphere. Tight covers on the mixers minimized the escape of odor into the mixing room. With the close capture hoods it was possible to reduce the air volume from 6,000 SCFM (9,462 Nm3/Hr) exhaust to 1,000 SCFM (1,577 Nm3/Hr) exhaust from the two process lines. The net air volume reduction of 82% reduced both the capital cost and the operating cost of the system.

In order to guarantee continuous production in the event of a burner failure, Anguil installed a bypass equipped with conventional roughing filters. The exhaust fan was equipped with an inlet vane control to vary the air volume if only one process line was being used. The control panel was outfitted with a user-friendly PLC first out detection system. The entire ceramic filter system was mounted in a light-weight enclosure to allow for roof mounting without significant structural modifications to the building. Growth capacity was accommodated in the gas burner and the fan section, allowing for the addition of future operations. Anguil’s system engineering provided their client with a solution to their compliance needs at reduced air volume and reduced cost.