Advanced Controls and Automation

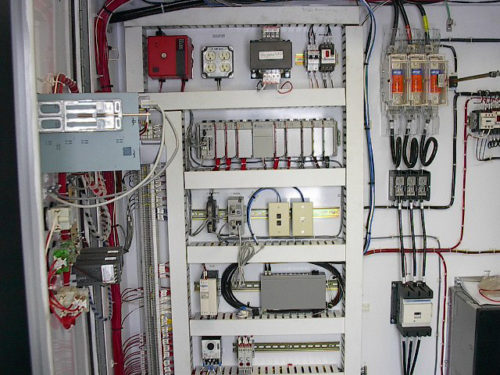

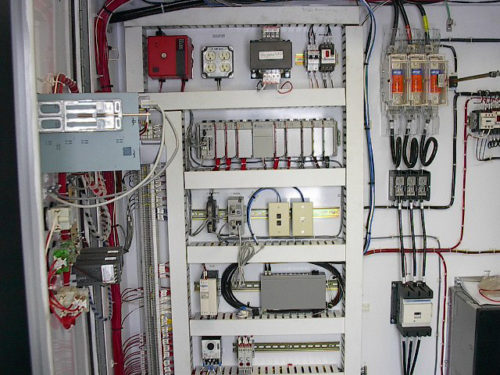

As controls and automation technologies have advanced, Anguil has updated our control systems to provide the safest, most efficient, and highly reliable operation while integrating smoothly into existing plant operations. From new equipment to upgrades and retrofits, our systems utilize the latest in Programmable Logic Controller (PLC) based controls, touch screen interfaces, and remote telemetry, resulting in a system which meets variable operational demands while limiting the necessary operator oversight.

Reliable Controls

Reliable operation is paramount to the success of any industrial controls package. Anguil believes a good design is a reliable design.  Designs should be resilient to downtime, account for safety and compliance risks, and optimize for usability.

Designs should be resilient to downtime, account for safety and compliance risks, and optimize for usability.

- Flexible Programmable Logic Controller (PLC) offerings allow operators and site personnel to work in programming environments they know and trust

- LCD color touch screens (6” to 15” screens available) translate the machine language into easy-to-operate controls and provide operators with meaningful feedback from system performance

- Remote access gateways simplify remote monitoring and troubleshooting

- Self-checking UV scanners and other smart devices bolster continuous operation

- Digital data recorders streamline compliance reporting by providing always-on encrypted data collection, ready at a moment’s notice

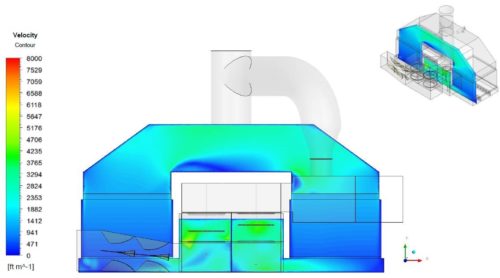

Efficient & Intelligent Design

Real-world experience and customer feedback converge with our prowess for electrical and mechanical engineering to create a design philosophy that works for today but looks to the future. The convergence of these ideals result in equipment that is both pragmatic and easy to operate, while also being intelligent and flexible, ready to take on new challenges in any industry.

- Variable Frequency Drives (VFDs) accommodate a wide range of process flows, minimizing OPEX by only processing as much flow as is needed

- Auto-balancing media beds optimize heat loading and transfer in regenerative systems

- Customizable Hot Gas Bypass (HGBP) offerings to handle excess heat, recover heat for preheating process flows, or fine-tune heat mass transfer

- Dynamic media bed and heat exchanger bypass controls mitigate periods of high process loading

- Optional Supplemental Fuel Injection (SFI) offerings to minimize NOx formation.

- Utilization of process measurements to control the dosing of treatment chemicals minimizes chemical costs and improves water treatment performance

Integrate with Confidence

Industrial equipment does not typically operate in isolation. Often, system and package integration are key to a facilities’ success. Anguil controls packages are designed with integration in mind and can easily integrate into already existing or future-planned equipment.

- Multiple inlet/pick-up point design with automated pressure control to balance disparate process exhaust flows

- Automatic fresh-air dilution responds to changes in process flows as independent pieces of equipment go online/offline

- A wide variety of control panel mounting/configuration options including on-skid, indoor and outdoor remote mounting, and free-standing control rooms

- Extra digital and analog I/O to accommodate future additions to controls and equipment

- Water treatment trains requiring a number of skidded components will operate together and with your facility seamlessly

- Remote Human Machine Interfaces (HMIs)

- Remote connectivity

In addition to thermal oxidizers, our electrical and programming engineers can integrate a wide number of additional equipment into a seamless control system including baghouses, scrubbers, heat exchangers, water treatment equipment, and other off-skid process controls. In all cases, controls integration can minimize the number of panels and operator touch points, saving in cost complexity. We provide remote HMIs and telemetry to allow operators to monitor the abatement equipment from their facility control rooms, production equipment or remote remediation sites.

Industrial Internet of Things (IIoT)

We always strive for continuous improvement at Anguil, which is why we have increasingly designed our technologies with sensing devices that utilize a central control system to remotely measure and adjust settings.

We always strive for continuous improvement at Anguil, which is why we have increasingly designed our technologies with sensing devices that utilize a central control system to remotely measure and adjust settings.

These smart devices utilize the Industrial Internet of Things (IIOT) to improve safety, reliability, and maintenance efforts. This functionality allows personnel inside and outside the plant to communicate with the Anguil system using native programming and an internet connection. Real-time data logging, event reporting, and alarm notification are just some of the benefits to IIoT. It is one of the easiest ways to expedite troubleshooting, reduce downtime, and enhance the value of routine preventive maintenance.

Anguil’s IIoT Platform and Pilot Program

Anguil has developed our own Industrial Internet of Things (IIoT) software platform and is currently seeking participants for our IIoT pilot program.

seeking participants for our IIoT pilot program.

Anguil’s IIoT software platform is tailored specifically for enhancing operational transparency and reporting capabilities for environmental pollution control equipment. Anguil partnered with Siemens to leverage their Mindsphere® software, which provides exceptional data security and complex development components and tools, allowing Anguil to develop a sophisticated, flexible, and data secure IIoT solution. Anguil’s IIoT platform is designed to leverage existing equipment data to improve performance, lower maintenance costs, and prevent unplanned downtime through graphical overviews, KPI dashboards, live trending, and document repositories.

You can read more about Anguil’s IIoT capabilities and to apply to the IIoT Pilot Program here.

At Anguil, we merge time-tested, standard products with innovative, custom-engineered solutions.

At Anguil, we merge time-tested, standard products with innovative, custom-engineered solutions.

industrial facilities. With thousands of successful installations around the world, Anguil’s engineering and system design expertise has consistently produced equipment effective at solving environmental challenges where others have failed. Simply put, Anguil engineers set us apart from the competition.

industrial facilities. With thousands of successful installations around the world, Anguil’s engineering and system design expertise has consistently produced equipment effective at solving environmental challenges where others have failed. Simply put, Anguil engineers set us apart from the competition.  project review is required before a go/stop decision is made.

project review is required before a go/stop decision is made.

Designs should be resilient to downtime, account for safety and compliance risks, and optimize for usability.

Designs should be resilient to downtime, account for safety and compliance risks, and optimize for usability. We always strive for continuous improvement at Anguil, which is why we have increasingly designed

We always strive for continuous improvement at Anguil, which is why we have increasingly designed

LCD Color touch screen Human – Machine Interface (HMI) (remote HMIs available)

LCD Color touch screen Human – Machine Interface (HMI) (remote HMIs available)