The Anguil Advantage

Carbon Fiber

Carbon fiber and composite materials revolutionize the products we use every day by making them stronger, lighter, and more durable. However, the manufacturing process can have serious environmental ramifications and be immediately dangerous to human health if careful consideration is not given to environmental control at the production phase of these materials.

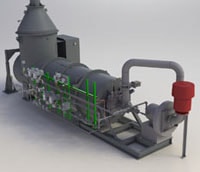

As is the case with many industrial manufacturing operations, emissions are best destroyed using thermal oxidation technologies via high temperature combustion. However, very few industries use custom designed solutions like the carbon fiber processing industry does.

Anguil has developed the most advanced air pollution control technologies currently used for carbon fiber and composite processes. Our proprietary designs offer high destruction efficiency, low greenhouse gas output and energy recovery options for powering process systems. State-of-the-art, field-proven technologies meet stringent environmental requirements for volatile organic compounds (VOCs), hydrogen cyanide (HCN), ammonia, silicone, nitrogen oxides (NOx), particulate matter, carbon monoxide, and odorous emissions. Anguil systems reduce the total plant operating costs by supplying 17% of the energy required for manufacturing. Abatement devices also incorporate features that decrease maintenance and increase process up-time.

Our systems were recognized for these capabilities by the U.S. Federal Government at their Oak Ridge National Laboratories (ORNL) as well as the University of Nottingham in the United Kingdom. Anguil continues to help producers drive down energy consumption and emission output.

Our integrated systems approach not only includes the oxidation equipment but also dust collection and heat recovery. With more turnkey systems in the field than any other supplier, we have listened to the maintenance concerns of our customers and designed our abatement systems to increase process up-time.

Composites

On composite applications, firms continue to battle emission levels by lowering styrene content in the resins they utilize. However, since styrene content affects product quality, fabricators are often limited using this control method. Other abatement strategies such as styrene suppressants and controlled spraying are often examined.

Anguil will make recommendations about airflow and styrene reduction strategies to make certain you are properly calculating your emissions. The result will be air volume reduction and higher capture efficiency requiring a smaller oxidizer with lower operating costs. Once minimum air volumes are determined, Anguil can select the appropriate oxidation technology. In addition, if a 100% Permanent Total Enclosure (PTE) is installed, expensive VOC capture tests can be avoided. If an extremely low VOC concentration condition exists, Anguil offers rotor concentrators that can be integrated with our oxidizers or retrofitted to your current abatement system for the realization of further efficiencies.

Anguil’s unsurpassed experience in both emission capture and airflow reduction allows us to become the perfect industry partner. Because pollution control equipment is sized and cost based on the volume of treated air, Anguil’s emissions experience is crucial.

For both carbon fiber and composites facilities with wastewater treatment needs, Anguil can be your single source provider of an integrated treatment train. We take a holistic approach to your application and explore all options for water reuse and onsite treatment. Anguil’s proven project development approach leverages attentive client collaboration, flexible exploration of viable treatments, rigorous solutions testing, and masterful integration with advanced controls and automation capabilities.

System Solutions

We custom engineer each solution, but Anguil finds the following technologies to be especially effective for carbon fiber and composites industry applications:

Applications

Applications